Tela Filtro: The Unsung Hero in Filtration Technology

In today’s world of advanced manufacturing and industrial processes, filtration is a critical component for ensuring safety, cleanliness, and operational efficiency. Among the many materials used for filtration, tela filtro—a Spanish term meaning “filter cloth”—has emerged as a versatile, cost-effective, and widely applicable solution in industries ranging from food processing to wastewater treatment.

This article explores what tela filtro is, how it works, its various types, applications, advantages, and future potential across different sectors.

Understanding Tela Filtro

Tela filtro refers to specially engineered cloth materials used for filtering solids from liquids or gases. These fabrics can be woven or non-woven and are typically made from synthetic fibers such as polyester, polypropylene, nylon, or natural fibers like cotton in specific applications.

Unlike ordinary fabrics, tela filtro is designed with specific pore sizes and permeability levels to control what passes through. This allows industries to capture unwanted particles, separate valuable materials, or prevent contamination efficiently.

How Tela Filtro Works

The basic principle of tela filtro is straightforward: as a fluid (liquid or gas) passes through the fabric, solid particles are trapped either on the surface or within the structure of the cloth. Over time, the accumulated solids may form a filter cake, which can further enhance filtration performance until the cloth needs cleaning or replacement.

Different filtering techniques include:

- Depth filtration: where particles penetrate into the cloth and are trapped within the fiber matrix.

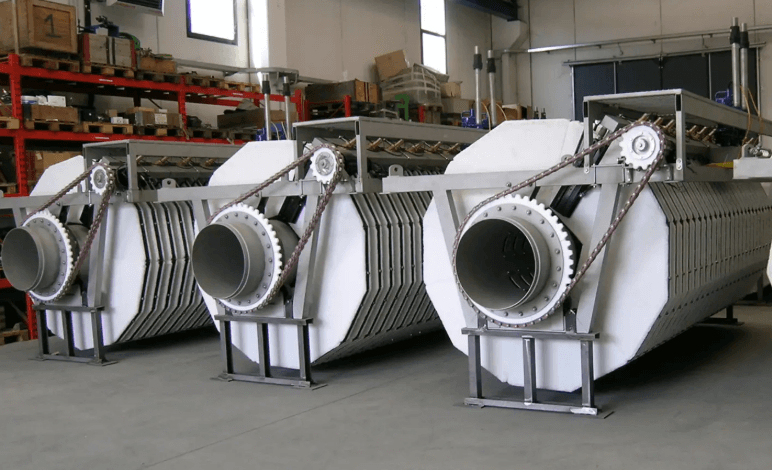

The fabric can be installed in filtration systems such as filter presses, rotary drum filters, belt filters, or even basic sieving setups depending on the complexity of the process.

See also: Technology in Commercial Cleaning: Innovations Shaping the Industry

Types of Tela Filtro

Tela filtro comes in a variety of materials and constructions, each with specific advantages for different uses:

Woven Filter Cloth

These are traditional tela filtro fabrics woven in various patterns (plain, twill, satin) to achieve a balance between strength and filtration capacity.

Non-Woven Filter Fabric

Produced through methods such as needle punching or thermal bonding, non-woven tela filtro offers uniform porosity and is especially useful in air filtration, face masks, and single-use filter bags.

Industrial Applications

Tela filtro plays a vital role in a wide range of industrial processes. Below are some of the key sectors where this material proves indispensable:

Wastewater Treatment

In municipal and industrial wastewater systems, tela filtro is used to separate sludge, trap debris, and aid in the dewatering process. Filter presses and belt presses use filter cloths to process waste and improve water recovery rates.

Food and Beverage Processing

Tela filtro is critical in filtering syrups, juices, dairy products, and edible oils. Its food-grade variants ensure that hygiene standards are maintained while filtering unwanted solids or residues.

Mining and Metallurgy

Mining operations depend on tela filtro to extract valuable minerals from slurry, manage tailings, and recycle water. High-strength cloths resist abrasion from coarse particles and aggressive chemicals.

Advantages of Tela Filtro

The widespread use of tela filtro stems from several core benefits:

- Customizable Porosity: Filter cloths can be tailored to meet exact filtration requirements, from coarse debris removal to fine particle separation.

- High Durability: Industrial-grade tela filtro materials withstand temperature extremes, chemical exposure, and mechanical stress.

- Cost-Effective: Reusable in many applications, filter cloths reduce operational costs over time.

- Low Maintenance: Easy to clean and replace, ensuring minimal downtime in critical processes.

Choosing the Right Tela Filtro

Selecting the most suitable tela filtro requires a thorough understanding of the process requirements:

- Material Compatibility: Ensure the fabric is resistant to the substances it will contact.

- Micron Rating: Applications like wine filtration may need sub-micron ratings, while wastewater treatment can use coarser fabrics.

- Mechanical Strength: High-pressure processes demand robust cloth that doesn’t tear or stretch under stress.

Maintenance and Cleaning

Maintaining tela filtro in good condition is essential for consistent filtration results. Cleaning methods include:

- Chemical Cleaning: Using solvents or detergents to dissolve residues.

- Mechanical Cleaning: Scrubbing or vibration to shake off particles.

Proper storage, regular inspection, and timely replacement ensure the longevity and efficiency of the tela filtro system.

Recent Innovations in Tela Filtro

The industry is witnessing exciting developments in tela filtro technology:

- Nanofiber-Enhanced Fabrics: These offer finer filtration and are used in critical filtration processes like air purification and medical-grade filtration.

- Biodegradable Filter Cloths: Eco-conscious versions made from cellulose or other biodegradable fibers offer temporary filtration with minimal environmental impact.

Future Outlook

With sustainability, efficiency, and smart manufacturing becoming central themes, the future of tela filtro looks promising. As industries seek to reduce waste and improve resource recovery, high-performance filter fabrics will play an even larger role.

Research into advanced polymers, smart fabrics with sensors, and automated cleaning systems continues to push the limits of what tela filtro can do. From clean water to clean air and product purity, this simple yet powerful fabric continues to support human development quietly and reliably.

Conclusion

Tela filtro may not grab headlines, but it plays a silent, vital role in the functioning of modern industry and environmental protection. Its ability to adapt to various needs—be it in food safety, waste management, or health care—makes it one of the most valuable materials in filtration technology.

From basic cloth to advanced nanofiber membranes, tela filtro continues to evolve, proving that sometimes the most effective tools are also the simplest in concept. As demand for cleaner processes grows, so too will the relevance of this remarkable material.